Global UV Stabilizers Market Set For Dynamic Growth And Innovation By 2034

Global Market Outlook: The Future of UV Stabilizers

The global UV stabilizers market is riding a wave of growth and opportunity, offering a fascinating look into an industry that touches everything from packaging to automotive materials, and even agriculture. On the surface, UV stabilizers may seem like one of those niche chemical compounds, but dig a little deeper and you’ll uncover a realm full of intriguing dynamics. This article explores the trends, opportunities, and challenges that shape the market, as well as how industries are benefiting from these compounds to enhance product durability.

Globally, the market is estimated to hit USD 1.57 billion in 2025 and is expected to climb to roughly USD 2.45 billion by 2034. This growth translates to a compound annual growth rate (CAGR) of just under 5%. Key reasons behind this steady progress include innovations in chemical formulations, rising demand in fast-developing sectors, and an increased focus on improving the longevity of products exposed to ultraviolet (UV) radiation.

With UV light posing a serious threat to the longevity of materials, products ranging from agricultural films to automotive coatings heavily rely on these chemicals. As industries take steps to sidestep the detrimental effects of UV radiation, UV stabilizers become not just helpful add-ons, but intrinsic parts of product manufacturing.

Understanding the Impact of UV Radiation on Materials

UV stabilizers perform the essential task of protecting materials from harmful ultraviolet light, a process that helps preserve color, texture, and structural integrity. Without these chemicals, everyday products—be it packaging materials, automotive components, or building supplies—would suffer rapid degradation caused by prolonged exposure to sunlight.

This protection is provided in several forms: hindered amine light stabilizers (HALS), ultraviolet light absorbers, quenchers, and UV shielding agents. Each plays a specific role in absorbing or reflecting UV rays, thereby shielding materials from the damaging effects of light. For instance, HALS have earned their spot at the forefront of the market, securing a revenue share of over 36% in 2025. Their effectiveness in preventing polymer degradation has made them a favorite among industries that produce coatings and plastics.

Key Drivers Behind Market Expansion

Growing Demand in the Automotive Industry

The automotive sector is emerging as one of the most significant demand drivers for UV stabilizers. This industry is constantly on the lookout for ways to improve the durability and aesthetic appeal of vehicles. UV exposure can lead to color fading and surface deterioration, making UV stabilizers a must-have in automotive manufacturing.

- The production of automobiles is surging in major markets like India, where every new vehicle incorporates UV stabilizers to ensure that paint and plastic components maintain their quality.

- With innovations in formulation, automotive parts are now better protected against the fading effects of sunlight, which in turn boosts consumer confidence and market demand.

- The fast-growing automotive market is also adapting to evolving environmental regulations, which pushes manufacturers to adopt sustainable, long-lasting materials that benefit from UV protection.

As automakers continue to expand their production lines, there is an increasing need for products that offer not only mechanical durability but also advanced aesthetic properties. UV stabilizers, therefore, provide a dual function—both preserving the visual appeal and structural performance of automotive components.

Innovations in UV Stabilizer Formulations

Recent innovations have significantly impacted the UV stabilizer market. Companies are constantly pushing the envelope with product development to mitigate the tricky parts of protecting various substrates. For example, liquid UV stabilizers provide a seamless integration into coatings and adhesives, thanks to their ease of use and effective performance.

In contrast, powder forms are now emerging as one of the fastest-growing segments. Manufacturers appreciate powders for their high resistance to heat and chemical degradation, which is particularly beneficial in high-performance industrial applications. From automotive parts to consumer electronics, the growing adoption of powder-based formulations reflects the market’s effort to address some of the tangled issues associated with traditional liquid and granular formats.

Furthermore, the development of advanced stabilizers capable of enhancing polyamide durability has opened new doors for industries such as automotive, construction, and consumer goods. The launch of innovative products that target specific deterioration challenges is expected to accelerate market growth further. When companies like BYK and Everlight Chemical Industrial Corp introduce breakthrough formulations, there is little doubt that the fine points of material science are being redefined.

Regional Trends: A Closer Look at Market Geography

Growth Trends in Asia Pacific

The Asia Pacific region stands as the global powerhouse in the UV stabilizers market, capturing nearly 45% of the revenue share in 2025. This dominance is attributed to robust industrial growth, advanced manufacturing processes, and strong demand in sectors like agriculture, packaging, and automobiles. Key players in countries such as China, India, and Japan are at the heart of these developments.

China, in particular, is noteworthy; its UV stabilizers market reached a valuation of USD 202.94 million in 2024, with forecasts predicting an increase to USD 215.12 million in 2025. Such numbers underscore the pivotal role the region plays in meeting the global demand for UV stabilizers.

Beyond sheer volume, Asia Pacific is also a hotbed for innovation. Companies in the region are investing in research and development to create eco-friendly formulations that not only offer excellent UV protective properties but also align with the growing green manufacturing trends around the world.

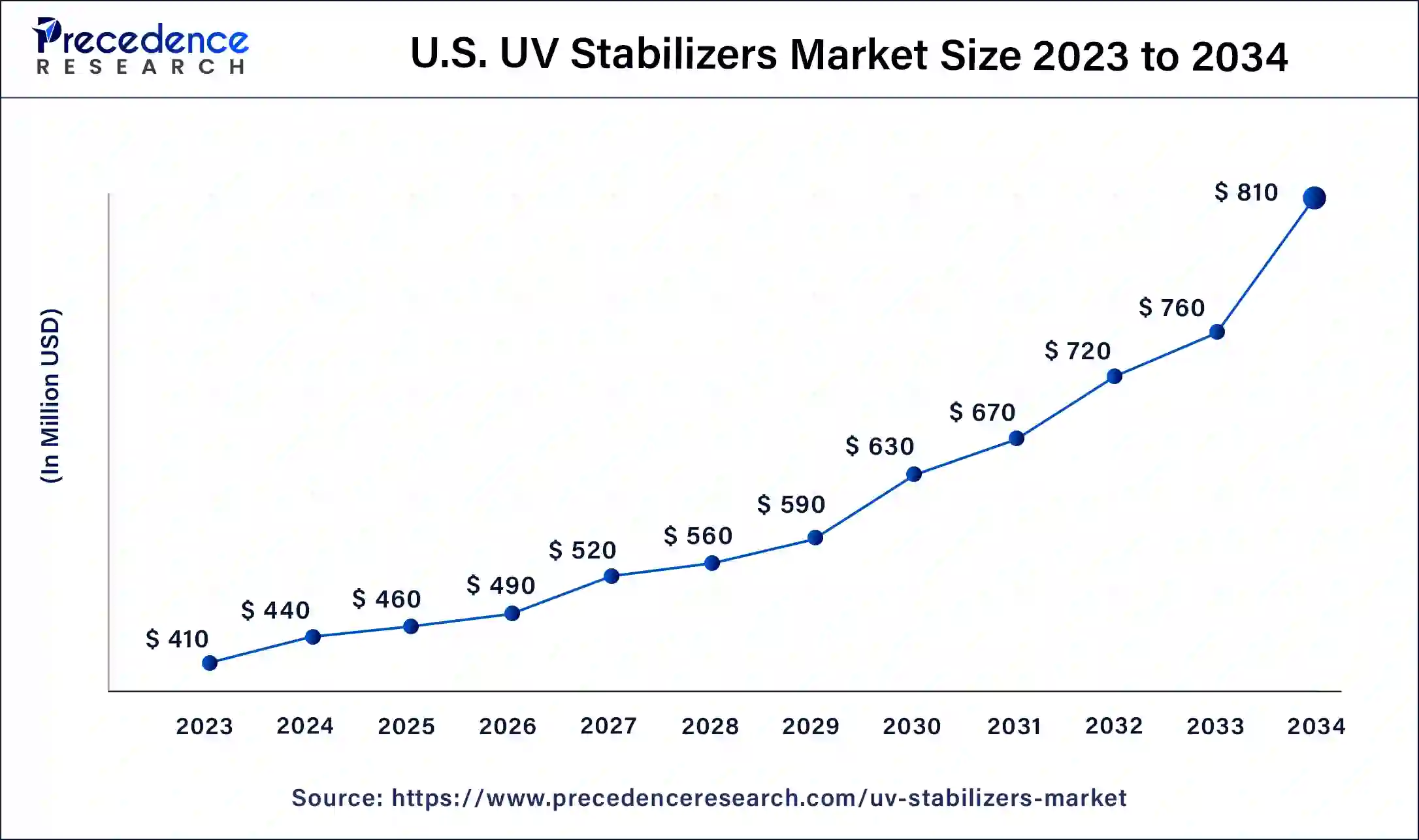

North America: Catching Up Quickly

While Asia Pacific currently takes the lead, North America is rapidly emerging as the fastest-growing region, with a CAGR of 6.95% between 2026 and 2034. In the United States and Canada, investments have been channeled into the development and production of high-performance UV stabilizers, bolstered by a well-established automotive sector and competitive innovation strategies.

Major market players, including BASF and ALTANA (BYK), are strategically expanding their product lines to cater to a variety of industrial needs. These developments create a robust framework that positions North America to overcome some of the tricky parts of competing directly with the well-established markets in Asia Pacific and Europe.

Furthermore, North American manufacturers are employing smart manufacturing techniques to optimize production costs and improve product quality. With consumer expectations shifting towards durable, eco-friendly, and reliable products, the region’s focus on high-performance UV stabilization is both timely and essential.

European Market Dynamics and Challenges

Europe’s UV stabilizers market is largely driven by a consistently growing construction industry. With extensive investments in both private and public infrastructure projects, the demand for durable, high-performance building materials continues to rise. UV stabilizers are used not only in coatings and plastics but also in critical applications like medical devices and packaging.

Germany, one of Europe’s leading construction markets, has seen significant growth due to its focus on improving the longevity of building materials. In the face of evolving regulatory standards and environmental policies, European players are compelled to innovate and find new ways to meet the demand for safer, more resilient products.

While the market is thriving, the region is also on edge because of the environmental challenges posed by the accumulation of certain UV stabilizers. The balance between technological innovation and ecological sustainability remains a nerve-racking issue that companies and regulators are working to address.

Emerging Markets in Latin America, Middle East, and Africa

Emerging markets in Latin America, the Middle East, and Africa show promising potential for the UV stabilizers market. Rapid urbanization, coupled with growing industrialization, is fueling demand across these regions. In Latin America, for example, increasing urban sprawl and infrastructural developments are pushing up the need for materials that offer prolonged durability—especially in packaging and construction.

Similarly, in the Middle East and Africa, there is a rising demand for UV stabilizers in the healthcare sector. The medical domain increasingly relies on these additives to protect sensitive devices and systems from polymer degradation. As healthcare expenditures continue to grow in countries like South Africa and Saudi Arabia, the need for advanced UV protection in medical and allied sectors becomes ever more critical.

Opportunities and Challenges Ahead

Exploring the Agricultural Sector

Agriculture represents a significant opportunity for UV stabilizers. Agricultural films, which are critical for crop production, face deterioration from prolonged UV exposure. Coating these films with UV stabilizers extends their service life, a breakthrough that can lead to increased yields and lower production costs. As countries focus on boosting food security and sustainable agriculture, the role of UV stabilizers gains even more importance.

For instance, Everlight Chemical Industrial Corp recently introduced Eversorb 990, a product specifically designed to protect agricultural films from environmental exposure. This innovation is likely to encourage further research into specialized UV stabilizers tailored for agricultural applications.

Additionally, advancements in material science and eco-friendly formulations will drive the agricultural sector forward. It’s not just about protecting the films; it’s about ensuring that agricultural practices are sustainable, cost-effective, and environmentally conscious.

Environmental and Safety Concerns

No market analysis would be complete without addressing the environmental challenges associated with UV stabilizers. Despite their undeniable benefits, these chemicals are under scrutiny for their potential to accumulate and cause toxicity. The environmental impact of plastic pollution, exacerbated by UV stabilizers, poses a tricky part that both manufacturers and regulators must manage carefully.

Recent studies have detected UV stabilizers like benzotriazole in various wildlife species, raising concerns about bioaccumulation. As these compounds travel through the food chain, they can have adverse effects on human and animal health. When the natural environment bears the brunt of such chemical accumulation, it becomes essential for companies to refine their products and invest in safer, more sustainable alternatives.

Efforts to introduce greener formulations and adhere to strict environmental regulations are critical. Manufacturers need to take the wheel in developing UV stabilizers that minimize toxicity while still delivering the super important protective benefits required by modern industries.

Innovative Product Developments: A Beacon of Progress

Recent product launches underscore how innovation is steering the UV stabilizers market. For example, BYK’s launch of BYK-MAX LS 4128 and Kao Corporation’s humidity-responsive UV protection films have not only addressed some of the challenging pieces of material degradation but have also set new benchmarks for performance and environmental safety.

These innovations serve multiple purposes:

- They extend the life and functionality of materials, whether in automotive components, packaging, or agricultural applications.

- They address the complicated pieces related to UV exposure by providing flexible solutions that react to environmental changes.

- They reduce long-term maintenance and replacement costs, offering manufacturers and consumers a cost-effective path forward.

As industries push for smarter products that can cope with the twists and turns of real-world usage conditions, the market is poised to introduce even more high-tech formulations. The integration of moisture control, heat resistance, and low-VOC properties in UV stabilizers marks a transformative shift that highlights the super important role these chemicals play.

How Different Forms of UV Stabilizers Cater to Diverse Needs

Liquid vs. Powder: Weighing the Options

The availability of UV stabilizers in multiple forms allows industries to choose solutions that are tailor-made for their applications. Liquid UV stabilizers, for instance, have enjoyed a dominant market share—around 46.5% in 2025—because they blend easily into formulations like coatings, adhesives, and flexible packaging. Their ease of use and consistent performance make them a popular choice in sectors where speed and reliability are on the agenda.

On the other hand, powders have emerged as one of the fastest-growing segments, with expectations of more than 6% CAGR over the coming years. Manufacturers are increasingly drawn to powders for applications in powder coatings used in automotive parts, appliances, and industrial equipment. Their robust performance under high temperatures and resistance to chemical degradation give them an edge when it comes to meeting stringent environmental regulations.

This dual format is significant because it allows companies to choose the best approach to meet their unique requirements while maintaining cost-effectiveness and performance efficiency. Ultimately, whether it’s a liquid or powder, the small details of formulation play a huge role in ensuring that products are well protected against UV exposure.

End-Use Applications: From Packaging to Personal Care

UV stabilizers are versatile ingredients that serve a wide variety of applications. The packaging industry, for example, benefits immensely from UV stabilizers because these chemicals help extend the shelf life of food, beverages, and pharmaceuticals by reducing the effects of UV-induced degradation.

In packaging, UV stabilizers are more than just protective additives—they provide a solution to the nerve-racking issue of product spoilage caused by sunlight. As global demand for durable and sustainable packaging materials grows, innovations in UV stabilization offer manufacturers a way to protect their products while reducing waste.

A similar trend is observed in the personal care and cosmetic sectors. With rising consumer awareness regarding skin health and conditions related to sun exposure, innovating in areas like smart UV films with moisture control is gaining momentum. These breakthrough products not only defend against harmful UV rays but also provide additional benefits, such as humidity responsiveness that transforms them into efficient forms of sunscreen. Such innovations exemplify how cross-industry technologies can create super important value for both consumers and manufacturers alike.

The Competitive Landscape and Strategic Moves

Industry Consolidation and Key Partnerships

The UV stabilizers market is characterized by its consolidated nature, where a few key players hold significant market share. Giants like BASF, Clariant, SONGWON, and ALTANA (BYK) have taken the lead by continuously engaging in new product developments, collaborations, and strategic market expansions.

For instance, Sarex Organics Pvt Ltd (Sarex Overseas) has carved a niche in manufacturing specialty chemicals for industries such as plastics, coatings, textiles, and agro films. Their strategic partnerships, such as the recent collaboration with Caldic, underline the importance of alliances in driving global reach. These partnerships are critical for companies to find their way through the maze of global markets, ensuring that quality products reach new customers across borders.

Competitive strategies in this market include:

- Expanding product portfolios through innovative R&D.

- Entering new geographical markets to tap into emerging demand.

- Collaborating with local distributors to enhance market penetration.

- Investing in sustainability initiatives to address environmental concerns.

Such strategic moves are essential in managing your way through the tricky parts of global market dynamics. As companies continuously refine their offerings and explore untapped territories, the overall market becomes more robust, diverse, and responsive to customer needs.

Current Strategic Initiatives and Their Impact

Recent developments within the industry have shown promising signs of growth and adaptation. For example, Everlight Chemical launched a liquid light stabilizer aimed at solving yellowing issues in silicone coatings, while Clariant has expanded its production in China to support applications such as artificial turf and medical devices. These strategic initiatives are not just isolated efforts. They represent a broader shift within the industry: a commitment to address the confusing bits and tangled issues associated with material degradation due to UV exposure.

Such bold moves provide a reliable roadmap for other companies aiming to do the same. By embracing innovation and aligning with market needs, these players are setting the stage for the next wave of technology-driven growth in the UV stabilizers sector.

Charting the Future: Trends and Predictions

Technological Advancements and Formulation Evolution

Looking ahead, one of the central trends to watch is the evolution of UV stabilizer formulations. As manufacturers continue to invest in research and development, the focus has shifted toward creating products that offer enhanced durability, reduced toxicity, and improved environmental compatibility. Future innovations may see products that are not only more effective in mitigating UV damage but are also aligned with global sustainability initiatives. With increasing regulatory pressures and consumer demand for green products, companies that prioritize sustainability will likely gain a competitive edge.

Some of the predictions for the future include:

- Development of multi-functional stabilizers that combine UV protection with anti-microbial and self-healing properties.

- Integration of nano-technology to create more efficient and targeted UV stabilization solutions.

- Enhanced eco-friendly formulations that minimize the negative impacts on the environment while maintaining performance.

- Greater collaboration between chemical manufacturers and end-use industries to create tailor-made solutions that meet performance and regulatory requirements.

These trends underscore the importance of innovation and flexibility in the face of evolving market needs. The ability to adapt to small distinctions in product performance and customer demand will be crucial for companies trying to figure a path through the increasingly competitive landscape.

Market Challenges: Tackling Environmental Concerns and Toxicity Issues

While the market is undoubtedly brimming with opportunities, it also faces some overwhelming challenges. One of the primary concerns is the environmental footprint of UV stabilizers. The potential for these chemicals to accumulate in ecosystems and cause toxicity is a problem that demands attention. Studies have revealed that certain UV stabilizers are present in wildlife at alarming levels, thereby necessitating stricter oversight and new, safer formulations to protect both human health and the environment.

To tackle these issues, manufacturers must invest in comprehensive research that prioritizes the long-term health of the environment. This includes:

- Developing products that minimize bioaccumulation and environmental persistence.

- Implementing sustainable production practices to reduce the overall carbon footprint.

- Adopting transparent quality control measures to ensure that products meet high safety standards.

Addressing these challenges head-on will require coordinated efforts among regulators, manufacturers, and end users. It is an intimidating yet necessary step towards ensuring that the benefits of UV stabilizers are not undermined by their potential risks.

Concluding Thoughts: A Market Poised for Innovation

In conclusion, the UV stabilizers market is a dynamic and evolving space that is set to redefine how industries manage product durability. With significant growth predicted for the coming decade, the market is full of promise—but it also comes loaded with issues that need careful attention. From innovations in automotive and packaging applications to strategic moves by leading chemical manufacturers, the industry is steadily working through its complicated pieces and environmental challenges.

The journey ahead is not without its tangled issues, yet the blend of technological advancement, strategic collaborations, and a stronger focus on sustainability provides a promising outlook. As we get into the nitty-gritty of market trends and dive into product innovations, it becomes clear that UV stabilizers are not just ancillary products—they are super important components shaping the future of material durability in a world where UV exposure is an unavoidable factor.

As industries worldwide continue to invest in smarter, more eco-friendly solutions, the role of UV stabilizers will only become more pronounced. The market is set to not only meet the tricky challenges posed by UV degradation but also serve as a testament to the power of innovation in overcoming even the most nerve-racking environmental issues.

Key Takeaways in a Nutshell

| Aspect | Highlights |

|---|---|

| Market Size | USD 1.57 billion in 2025, projected to reach USD 2.45 billion by 2034 |

| Growth Drivers | Agriculture films, automotive demand, innovative formulations, packaging applications |

| Regional Leaders | Asia Pacific dominates; North America leading in growth |

| Product Formats | Liquid (dominant) and Powder (fast-growing) |

| Challenges | Environmental concerns, toxicity, bioaccumulation issues |

Looking Ahead: What Should Industry Stakeholders Focus On?

For manufacturers and end users alike, the future of UV stabilizers hinges on a few key priorities:

- Investing in R&D to create more efficient, sustainable products.

- Forming strategic partnerships to enhance market reach and product development.

- Addressing environmental challenges with greener, dose-optimized formulations.

- Leveraging technology advancements such as nano-enhanced stabilizers and smart formulation techniques.

- Staying agile in an ever-changing regulatory landscape to ensure compliance and safety.

By focusing on these critical areas, industry stakeholders can steer through the twists and turns of this competitive market. There is a strong push for solutions that not only deliver in terms of performance but also ensure the long-term health of our environmental resources.

A Final Reflection

The UV stabilizers market epitomizes the delicate balance between technological progress and environmental responsibility. As industries come together to protect products from degrading under the harsh rays of sunlight, the need for innovative, sustainable solutions becomes ever more clear. The market’s upward trajectory is a testament to the ingenuity of chemical manufacturers, the resilience of various industrial sectors, and the collective drive to overcome intimidating environmental challenges.

For those in manufacturing, consumer goods, and automotive sectors, the adoption of advanced UV stabilizers offers not only a solution to current issues but also a glimpse into a future where materials are designed to withstand both the test of time and the impact of environmental forces. As we take a closer look at the market’s evolution, it is evident that the UV stabilizers segment will continue to innovate and expand, making it a cornerstone for industries that demand long-lasting quality in an ever-changing world.

In the end, by working through the confused bits and managing your way around the tricky parts of product degradation, the industry is not just finding a way to survive—it’s laying the groundwork for a resilient future. One where UV stabilizers not only protect materials from the damaging effects of sunlight but also contribute to a broader vision of sustainable industrial growth and innovation.

Final Thoughts and Recommendations

As the market matures, stakeholders should keep an eye on the following recommendations:

- Continuously assess market dynamics and adjust product strategies to stay competitive.

- Invest in technologies that address the small distinctions between various product applications, thereby enhancing performance.

- Engage with regulatory bodies and environmental groups to ensure that innovations align with broader sustainability goals.

- Explore cross-industry collaborations that leverage the strengths of different sectors, from agriculture to automotive.

- Remain proactive in research and innovation to keep ahead of emerging trends and potential environmental concerns.

By embracing these strategies, industries can create a robust ecosystem for UV stabilizers—one that not only improves product longevity and performance but also supports a vision for a greener, more sustainable future. The industry’s journey is a testament to the power of small yet super important innovations that, over time, translate into far-reaching benefits for the entire global market.

In wrapping up, the UV stabilizers market stands as a beacon of innovation at the intersection of chemical science and industrial application. With promising growth avenues in automotive, packaging, agriculture, and beyond, the sector embodies the synergy of advanced technology and practical flair. While challenges remain—environmental concerns being at the forefront—the ongoing commitment to research and sustainability paves the way for an exciting, resilient future.

Originally Post From https://straitsresearch.com/report/uv-stabilizers-market

Read more about this topic at

UV Stabilizers Market, Industry Size Growth Forecast …

UV Stabilizers Market Size & Share | Global Report [2032]