Timing Gear Market Growth Accelerates With Four Point Five Percent Annual Increase

Global Timing Gear Market: A Comprehensive Opinion Editorial

The global timing gear market serves as a cornerstone for synchronizing engine operations, and its evolution is as compelling as it is critical. In this opinion editorial, we take a closer look at the market’s growth, emerging trends, and the challenges that manufacturers face. Spanning over automotive, aerospace, and industrial sectors, timing gears are essential components that play a super important role in engine performance and overall machinery efficiency.

Over the next sections, we’ll examine the market dynamics, highlight key drivers, and discuss how technological innovations are reshaping the industry landscape. By digging into the various dimensions of the timing gear market, we aim to provide a neutral analysis backed by practical insights to help readers understand both the opportunities and the tricky parts of this sector.

Global Market Overview: Growth Projections and Industry Impact

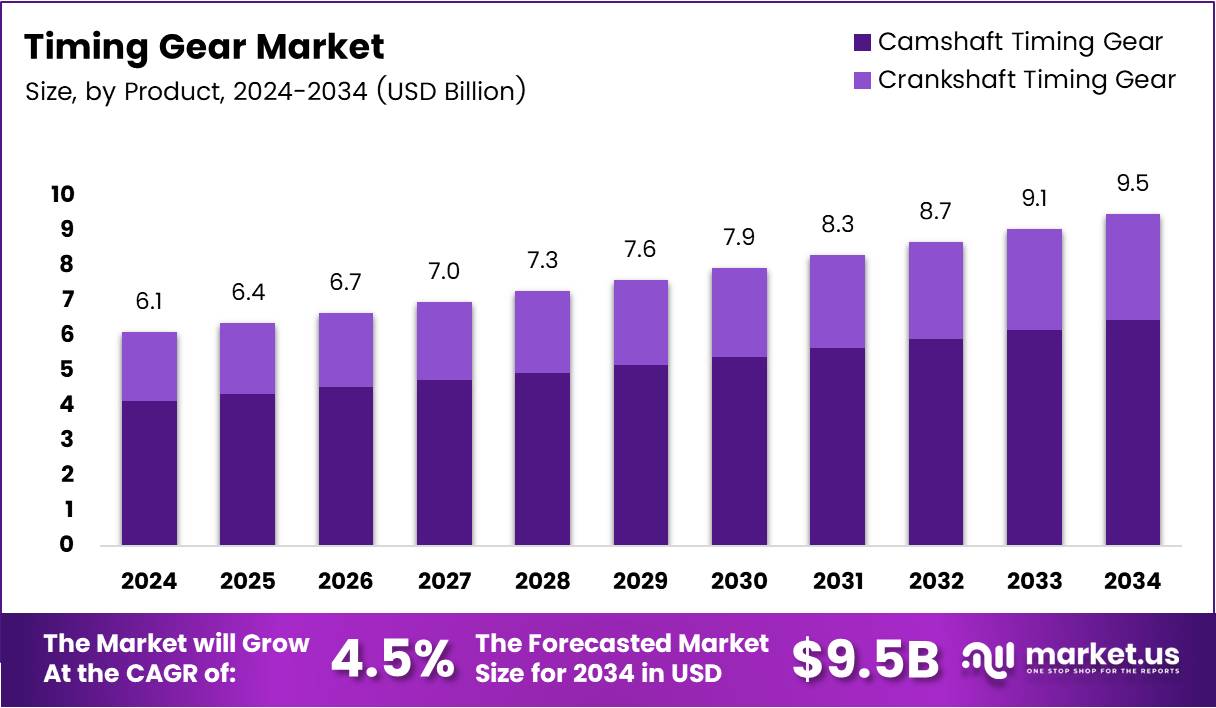

According to recent analyses, the global timing gear market is expected to be worth around USD 9.5 billion by 2034, rising from USD 6.1 billion in 2024. This sustained growth, reflected in a 4.5% compound annual growth rate (CAGR), underscores the market’s importance. While the market is expanding steadily, it is also loaded with issues that require manufacturers to adjust to evolving demands.

Timing gears are not merely transmission parts; they are the key to ensuring that engine cycles are aligned with optimal performance. As automotive production increases around the world—especially in emerging economies—manufacturers are pressed to offer components that address both efficiency and the tricky parts of maintenance. This editorial examines how these gears are pivotal in connecting premium vehicle engineering with demand-driven innovations.

Long-Term Market Expansion and Economic Influences

Government investments in infrastructure and industrial projects are a super important force shaping this market. With industrial machinery upgrades and enhanced manufacturing facilities globally, there is a growing need for precise timing mechanisms in construction, mining, and heavy-duty equipment sectors. The boost in infrastructure spending directly correlates with increased demand for reliable and high-performance timing gears.

Furthermore, the automotive industry’s global expansion and the increased adoption of electric and hybrid vehicles create a dynamic environment for manufacturers. These vehicles, while having different requirements compared to traditional combustion engines, still rely on timing components to maintain performance integrity. As such, manufacturers are challenged to integrate modern technologies that not only meet these needs but also address the fine points of emerging safety and performance standards.

Key Drivers in the Automotive Timing Gear Sector

Driving the rapid transformation of the timing gear market are several important factors. Here we break down the primary drivers that are fuelling growth across the sector.

Rising Demand for Advanced Engine Technologies

Modern automotive systems require very sophisticated timing gears to ensure that engine operations are smooth and reliable. Improved engine performance, better fuel efficiency, and reduced emissions have become central to the automotive narrative. Manufacturers are now focusing on precision engineering, incorporating advanced materials, and committing themselves to research and development. This approach is aimed at significantly reducing the complicated pieces of engine timing issues.

This focus aligns well with consumer demand for vehicles that offer both performance and efficiency. New materials not only improve durability and reduce the overall weight of components but also promise enhanced longevity. By finding innovative solutions that cater to these emerging engine designs, the industry is set to witness continued growth.

Expansion of Global Automotive Production

The increase in global vehicle production, driven largely by rising demand in developing countries, is another significant growth factor. As vehicle manufacturing scales up, especially in regions such as Asia Pacific and Latin America, the need for high-precision timing gears escalates. This high-volume production environment offers both challenges and opportunities. Manufacturers are encouraged to optimize production processes, reduce production time, and lower costs while simultaneously maintaining stringent quality standards.

Key bullet points in this area include:

- Increased vehicle assembly lines in emerging economies.

- Greater emphasis on fuel efficiency in design.

- Adoption of advanced testing to ensure long-term performance.

- Enhanced focus on cost-effective materials and production methods.

Evolution of Electric and Hybrid Vehicle Technologies

While electric vehicles (EVs) and hybrid technologies are redefining the automotive landscape, they also present new challenges. Though EVs require timing components in various mechanical systems, their integration into timing gear design calls for innovation and adaptation. Manufacturers who adjust their product portfolios to meet these nerve-racking electrical and mechanical integration challenges are likely to secure a competitive advantage.

This evolution is generating a need for products that can perform well under diverse operating conditions, whether in a high-performance sports car or fuel-efficient daily driver. The transition is prompting the industry to incorporate smart, lightweight materials and to further innovate their production techniques—a move that promises to refine the core aspects of traditional timing gears.

Product Types in Timing Gear: Camshaft vs. Crankshaft

In the timing gear market, two product types make up the majority of demand: camshaft timing gears and crankshaft timing gears. Each type plays a unique role in engine performance, and understanding their contributions is key to appreciating the market dynamics.

Camshaft Timing Gears: The Backbone of Valve Operation

Camshaft timing gears are responsible for regulating the intake and exhaust valves by ensuring precise timing. In 2024, camshaft gears held a dominant market share of around 67.1% in the product segment. These gears are crucial not only for maintaining engine cycles but also because they need regular maintenance and replacement. With their widespread application across different engines, they continue to drive the market substantially.

Important insights include:

- They are essential for controlling valve operations.

- Regular maintenance fuels a reliable aftermarket.

- Technological enhancements have improved their durability.

Crankshaft Timing Gears: Synchronizing Engine Cycles

Crankshaft timing gears are integral for synchronizing the rotations between the crankshaft and the camshaft. Although their market share is lower when compared to camshaft gears, they play a supportive role in overall engine performance. Crankshaft gears tend to have a longer lifespan, translating to fewer replacements but a consistent demand for their precision engineering.

Manufacturers are currently focused on innovating in materials and design to not only extend the lifespan but also to handle the increasing performance expectations that come with modern engine designs. By emphasizing improvement in these fine points, companies are positioning themselves strongly for future automotive trends.

Engine Types: Inline Engines Versus V-Engines

The engine type plays a critical role in determining the nature and demand for timing gears. In 2024, inline engines captured a dominant market share of about 69.3% due to their simpler design and widespread use in automobiles.

Inline Engines: Simplified Designs for Mass Production

Inline engines are preferred for their straightforward design and production efficiency. Their linear configuration simplifies the timing gear layout, making it an attractive option for mass production. This ease of integration translates directly into reduced production costs and better fuel economy, making inline engines a favorite choice for both manufacturers and consumers alike.

Key benefits of inline engines include:

- Simpler timing system configuration.

- Less involvement in complicated pieces, meaning fewer tangled issues during manufacturing.

- High production volumes leading to economies of scale.

V-Engines: Balancing Complexity and Performance

Unlike inline engines, V-engines require a more complicated timing gear configuration due to their dual-cylinder bank design. Despite the additional twists and turns in their design, V-engines are favored for high-performance applications. They deliver superior power output and enhanced performance, which is critical in premium and luxury vehicles.

While V-engines inherently come with additional challenges in production, their role in driving high performance is undeniable. Manufacturers must invest in sophisticated testing and quality assurance mechanisms to make sure that these components meet the expected standards in extreme conditions.

Sales Channels: OEM Dominance and Aftermarket Opportunities

The sales channel through which timing gears are distributed also plays a crucial role in market dynamics. In 2024, the original equipment manufacturer (OEM) segment overwhelmingly dominated with around a 72.5% market share.

OEM Relationships: Building Long-Term Collaborations

OEM channels benefit from long-standing relationships with automotive manufacturers. These channels usually secure long-term contracts and bulk purchasing agreements, providing manufacturers with a steady revenue stream. For the OEM segment, quality and consistency are super important; manufacturers are pressed to meet strict quality standards while keeping pace with evolving engine designs.

Key points to note include:

- Long-term relationship building with established car manufacturers.

- Bulk procurement helps stabilize revenue flows.

- Integration of technical expertise and advanced design into product upgrades.

Aftermarket Channels: Catering to Replacement and Maintenance Needs

Aftermarket channels cater to the replacement and maintenance segment of the market. As vehicles age, the demand for replacement timing gears steadily increases. This market segment is bolstered by the need for regular maintenance and servicing in both passenger and commercial segments. Independent repair shops and distributors increasingly rely on aftermarket products to meet ongoing service demands.

Digital transformation is also influencing both OEM and aftermarket channels. Online platforms now provide increased accessibility and improved customer service, thereby expanding market reach and enhancing operational efficiency.

Regional Analysis: Differing Perspectives Across the Globe

The timing gear market is highly regionalized, with differences based on economic power, automotive production capacity, and technological adoption. A closer look at key markets reveals both opportunities and distinctive challenges.

North America: Leading with Advanced Manufacturing

North America currently holds a dominant market position, with 37.3% of the total market share valued at approximately USD 2.2 billion in 2024. This region benefits from advanced automotive technology and stringent emission standards, which in turn boost demand for precision-engineered components. Moreover, the presence of major automotive manufacturers ensures a steady demand for high-quality timing gears.

Key elements in North America’s success include:

- Advanced manufacturing techniques and quality control.

- Strict environmental and safety regulations that push for technological innovation.

- A large and diverse automotive production base.

European Market Trends: Emphasis on Quality and Performance

Europe’s timing gear market is characterized by a strong focus on performance, efficiency, and the enforcement of rigorous emission standards. Automotive manufacturers in Europe are increasingly investing in advanced materials and innovative production processes to meet regulatory standards and consumer expectations. This technological drive is fostering robust growth in the region, despite the challenging bits of meeting various regulatory guidelines.

Distinct features of the European market include:

- Heavy emphasis on quality and reliability in product manufacturing.

- Strong integration of advanced automotive technologies.

- The impact of stringent emissions and safety regulations driving innovation.

Asia Pacific: Rapid Expansion Amidst Growing Demand

The Asia Pacific region is emerging as one of the fastest-growing markets. Driven primarily by countries like China, India, and Japan, this region is experiencing rapid expansion in vehicle production and automotive parts manufacturing. The increasing disposable income, urbanization, and rising middle-class population contribute significantly to this market growth.

Important regional highlights include:

- Robust expansion in vehicle production and manufacturing capabilities.

- Growing adoption of advanced and eco-friendly engine technologies.

- Rapid modernization of infrastructure supporting automotive innovation.

Latin America and Middle East & Africa: Emerging Yet Promising

While the Latin American market is witnessing steady growth propelled by rising automotive production in countries like Brazil and Mexico, the Middle East and Africa are slowly developing streams in timing gear demand. In these regions, economic development and rising vehicle ownership are gradually intensifying the need for high-performance automotive components.

Key attributes include:

- Steady growth driven by increasing vehicle ownership and demand for fuel-efficient vehicles.

- Growing interest in maintaining and upgrading industrial and automotive parts.

- A promising outlook as local manufacturing capabilities mature over time.

Technological Advancements: Transforming the Timing Gear Industry

Technology continues to reshape the timing gear landscape. Emerging processes like 3D printing and additive manufacturing are not only reducing production costs but also enabling greater customization. Manufacturers now face the challenge of integrating smart technology systems into their processes, a shift that can sometimes seem intimidating. However, these innovations also pave the way for improved efficiency and faster production cycles.

Integration of Smart Automotive Systems and Digital Platforms

One of the most important trends in the industry is the incorporation of smart systems into automotive technologies. Modern vehicles are increasingly laden with electronic control systems that require very precise timing coordination. Timing gears integrated with smart sensors and digital control mechanisms can dramatically enhance vehicle performance and lower operational costs. This development not only delivers better engine synchronization but also enables predictive maintenance, thereby reducing overall downtime.

The notable benefits of these smart integrations are:

- Enhanced precision in engine performance.

- Real-time monitoring for preventive and predictive maintenance.

- Improved overall performance and fuel efficiency.

The Role of 3D Printing in Reducing Production Costs

3D printing is one of the technological game changers in manufacturing. This approach allows companies to quickly produce prototypes, make customizations, and even move towards low-volume production processes efficiently. The application of additive manufacturing has a significant impact on producing components with complex designs and reducing the wait time for replacement parts. This method enables companies to produce the fine points of product design with greater accuracy and quicker turnaround times than traditional methods.

Some advantages of 3D printing include:

- Rapid prototyping and decreased development cycles.

- Customization of timing gears to meet very specific requirements.

- Cost-effective production that optimizes resource utilization.

Regulatory Challenges and Quality Assurance in Manufacturing

Although the market outlook is promising, manufacturers face several regulatory and quality challenges that can be overwhelming. The production of automotive components involves compliance with strict safety norms and environmental regulations, which often translate into increased production costs. In many parts of the world, these guidelines are not only designed to ensure safety but also to push companies to innovate continuously.

Stringent Guidelines and Increasing Compliance Costs

Governments worldwide are imposing stricter standards on automotive components. These guidelines compel manufacturers to invest in advanced testing procedures and quality assurance technologies. While these requirements help ensure that products are safe and meet performance benchmarks, they also introduce additional production challenges such as higher material costs and labor expenses.

Some factors contributing to regulatory challenges include:

- Frequent updates to safety and environmental regulations.

- Increased costs associated with compliance and testing.

- Risks involved with fluctuating raw material prices.

Quality Assurance and the Need for Consistency

Maintaining consistent quality is essential, and it requires manufacturers to focus on the little details and fine shades in production processes. Regular maintenance of timing gears, combined with rigorous quality control standards, helps curb the risk of failures. However, quality assurance can be one of the trickier parts of production—demanding investments in technology, workforce training, and continuous process improvements.

To sum up the key aspects:

- Implementing advanced quality control measures is super important.

- Consistent monitoring of production practices is essential to maintain high standards.

- Investments in technology and streamlined processes help manage these complicated pieces.

Opportunities in Aftermarket Services and Technological Innovation

Despite the challenges introduced by regulatory pressures and rising production costs, the timing gear market is brimming with opportunities. One such opportunity is the expansion of automotive aftermarket services. As vehicles age and require maintenance or replacement of specific components, demand for aftermarket timing gears continues to grow.

Aftermarket Growth: A Sustained Revenue Stream

The aftermarket segment is flourishing due to the steady increase in vehicle longevity and an expanding global vehicle fleet. Independent repair shops and service centers play a crucial role. They make your way through the maintenance demands by sourcing high-quality replacements that uphold the performance standards set by original equipment manufacturers. This segment not only supplements the revenues derived from OEM sales but also adds to the industry’s resilience during economically challenging times.

Key benefits of a strong aftermarket include:

- Consistent demand due to aging vehicle fleets.

- Opportunities for technological upgrades in component design.

- Enhanced customer satisfaction through quality spare parts availability.

Leveraging Technological Innovations for Market Expansion

The sector’s growth is further amplified by embracing innovations such as automation, robotics, and smart manufacturing. These advancements allow manufacturers to streamline production processes, reduce labor costs, and improve product quality. As companies start to incorporate digital tools and automation in their manufacturing pipelines, the efficiency of production cycles improves significantly. This digital transformation is a key area where traditional manufacturing processes are slowly merging with modern technological practices.

This integration creates a competitive advantage by:

- Reducing production lead times and costs.

- Enhancing precision and consistency in production output.

- Facilitating quick adaptation to new regulatory standards.

Environmental Considerations and the Shift to Sustainable Manufacturing

In today’s eco-conscious world, sustainable manufacturing practices are more than just a trend—they are a necessity. The timing gear industry is gradually aligning with green initiatives, ensuring that production methods are less harmful to the environment. Manufacturers are increasingly exploring cleaner production techniques, recycling programs, and responsible raw material sourcing methods.

Sustainable Manufacturing: Balancing Efficiency and Environmental Responsibility

Sustainable practices in the timing gear industry not only help reduce the carbon footprint but also offer long-term cost benefits. By using advanced alloys and composite materials, companies can reduce waste, lower energy consumption, and improve the overall efficiency of their operations. While implementing such processes can appear intimidating and off-putting at first, the long-term benefits far outweigh the initial challenges.

Main aspects of sustainability in manufacturing include:

- Adoption of eco-friendly materials and production processes.

- Efforts to reduce energy consumption and waste generation.

- Enhanced recycling programs and responsible sourcing of raw materials.

Consumer Demand for Environmentally Responsible Products

Today’s consumers are more aware of environmental issues than ever before. As a result, automotive manufacturers and parts suppliers are increasingly under pressure to offer sustainable, energy-efficient products. This demand translates into a market opportunity for timing gear producers who invest in green technologies and processes. Companies that make your way through the challenges of integrating sustainable practices will likely benefit from regulatory incentives and heightened brand loyalty.

Future Outlook and Strategic Adaptation

Looking ahead, the timing gear market is poised for ongoing evolution due to continuously emerging trends and shifting industry priorities. Integration of electric vehicle technologies, growing global production capacities, and strategic investments in automation and digital platforms are just a few of the factors that will shape the future landscape of this market.

Strategies for Market Adaptation and Growth

Companies looking forward to maximizing their market potential must figure a path both in product innovation and operational agility. Here are some strategic routes that can be adopted:

- Product Diversification: Expanding product offerings to include specialized timing gears for electric and hybrid vehicles can significantly boost competitiveness.

- Technological Upgrades: Investing in digital manufacturing tools and automation will enhance efficiency and precision.

- Geographic Expansion: Expanding market reach, particularly in emerging regions like Asia Pacific and Latin America, can provide access to untapped demand.

- Sustainable Practices: Prioritizing eco-friendly production methods can not only help in compliance but also improve brand reputation.

Industry Collaboration and Innovation

Collaboration within the industry is another key strategy. Partnerships between established firms and startups focused on advanced manufacturing techniques can drive innovation. By sharing knowledge and resources, companies can address the confusing bits of the production process, streamline supply chains, and enhance overall product quality. This cooperative approach not only mitigates risks but also fosters sustainable growth, benefiting the entire automotive ecosystem.

Recent collaborations and acquisitions have shown that companies willing to take calculated risks to integrate advanced materials and smart systems are likely to succeed. These partnerships often result in access to innovative research, increased distribution channels, and improved market responsiveness.

Closing Thoughts: A Dynamic and Evolving Landscape

In conclusion, the global timing gear market embodies a blend of technological innovation, market expansion, and regulatory challenges. The steady growth forecast of reaching USD 9.5 billion by 2034 is a testament to the indispensable role timing gears play in ensuring engine synchronization across various industries—from conventional automotive systems to the latest electric and hybrid vehicles.

While manufacturers must continuously make their way through the new twists and turns such as rising production costs, regulatory changes, and an increasing focus on sustainability, the opportunities for those who invest in advanced technologies and sustainable practices are immense. The market is clearly evolving—driven by both the expansion of traditional vehicle manufacturing and the innovative shift towards green, connected, and smart automotive solutions.

It’s important for industry professionals to dive in and take a closer look at these changes. As emerging technologies like 3D printing and digital automation become more integrated into manufacturing processes, companies that are agile enough to adapt will undoubtedly maintain a competitive advantage in the global market. The path may seem intimidating at times, yet the rewards of steering through these complicated pieces are significant and offer a glimpse into a future where precision and reliability are paramount.

Key Takeaways: The Road Ahead

To summarize the insights explored in this editorial:

- The timing gear market is expected to experience steady growth driven by increased global vehicle production and technological advances.

- OEM channels currently dominate, yet the aftermarket serves as a consistent revenue source as vehicles age.

- Innovations in materials, smart technology integration, and 3D printing are transforming production methods.

- Geographical trends show North America and Europe leading in technological advancement, while Asia Pacific and Latin America offer significant growth potential.

- Sustainable manufacturing practices and eco-friendly production methods are becoming essential in meeting regulatory requirements and consumer demands.

- Future strategies should focus on product diversification, technological upgrades, and strategic industry collaboration to effectively find your way through emerging challenges.

This dynamic market demands that industry players make well-informed decisions to adapt and innovate continuously. As global trends shift and the demand for sophisticated automotive technologies rises, those who can balance traditional practices with modern advances will remain at the forefront of the industry.

Looking to the Future: Embracing Change and Opportunity

Ultimately, the future of the timing gear market rests on the industry’s ability to manage its fine points while delivering products that meet emerging performance and sustainability standards. The intricate balance between traditional manufacturing practices and modern digital innovations creates both challenges and promising opportunities for growth. By staying mindful of the regulatory environment, investing in advanced technologies, and building strong partnership networks, manufacturers can confidently take the wheel and shape the future of automotive components.

As we move into the next decade, the market will undoubtedly encounter both nerve-racking challenges and exciting possibilities. It is an exciting journey that requires industry insiders to continuously get into the fine points of every new technology, every material innovation, and every regulatory change. This adaptability is what will ensure the industry not only survives but thrives in the long run.

Final Reflections

In this editorial, we have seen that the evolution of the timing gear market is more than just a story of numbers and projections. It is a tale of innovation, precision, and strategic adaptation in the face of ever-changing demands and regulatory landscapes. For those involved in the automotive and industrial manufacturing sectors, understanding these trends is key to making informed decisions that drive future success.

By embracing both the technological advancements and the sustainable practices that define the modern era, the timing gear industry is set to deliver not only improved engine performance but also contribute to a more environmentally responsible manufacturing ecosystem. As we look ahead, the ability to find your way through the tricky parts, tackle the small distinctions of regulatory complexity, and implement groundbreaking new technologies will be the true measure of success in this pivotal market.

Originally Post From https://market.us/report/timing-gear-market/

Read more about this topic at

Timing Devices Market Size, Share & Growth Report, 2030

Precision Timing to Power the Future Montage Technology …